VRV R - Heat Recovery

-

Available in

Reverse Cycle (Heating & Cooling)

-

Heat Recovery

Standard: 22.4kW-169kW, Hi COP: 44.8kW-89.4kW

-

RefrigerantR410A

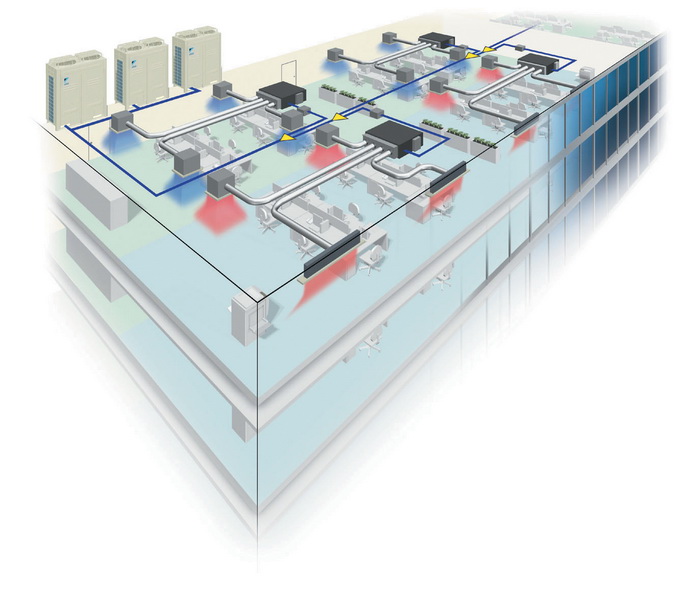

To meet the complex heating and cooling requirements of the modern office building, Daikin’s VRV IV Heat Recovery is able to simultaneously heat and cool different parts of the building. In doing so, the Heat Recovery process that is occurring allows waste heat from one part of the building to be redirected to another that requires heating resulting in a system that provides superior comfort levels at significant energy efficiency gains compared to conventional HVAC systems.

Minimum Energy Performance Standards

-

Features

- VRV IV Heat Recovery units allow for simultaneous cooling and heating from one system

- Up to 64 indoor units can be connected to a single outdoor system

- Continuous operation -5 to 43°C Dry Bulb in cooling mode, -20 to 15.5°C Wet Bulb in heating mode and -6 to 15.5°C in cooling & heating mode

- High External Static Pressure (ESP) of 78.4Pa on condenser fans

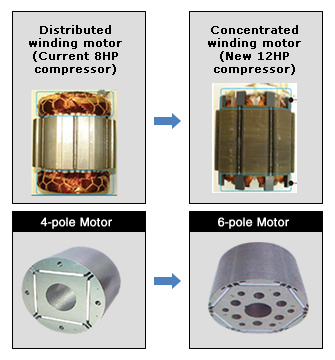

- Use of new high tensile strength material and Thixocasting manufacturing process has enabled the development of a new compact and efficient scroll compressor, i.e. 12 class (33.5kW) compressor utilizing 8 class (22.4kW) casing. Daikin's optimized large capacity inverter scroll compressor designed specifically for R-410A is compact, quiet and highly efficient

- Daikin's new compressor utilizes a 6 pole motor instead of a 4 pole motor with 50% more neodymium magnets to improve efficiency and reliability

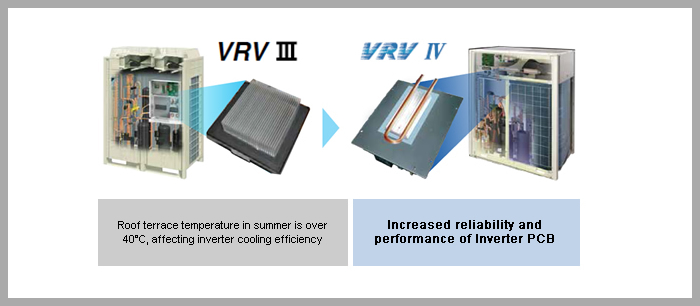

- Refrigerant Cooled PCB to ensure reliability, stability and longevity of the unit under the harsh summer heat

- Daikin's system management and oil-equalizing technology ensures maximum reliability and design flexibility of the system, with piping runs of up to 165m with maximum level difference of 90m between indoor and outdoor units (via field setting only) and a total networked length of up to 1,000m.

- Low operation noise, a result of efficient heat exchanger design, streamlined air grille and re-designed scroll condenser fans

- Anticorrosion treatment applied on exterior metal casing and heat exchanger

- Fully compatible with the complete Daikin control suite including the Intelligent Touch Controller, the Intelligent

Variable Refrigerant Technology

Daikin's VRV IV Heat Recovery now features Variable Refrigerant Temperature technology (VRT), a state of the art energy saving technology that automatically adjusts the refrigerant temperature as the building load varies to maintain optimum comfort conditions whilst keeping operational costs low.

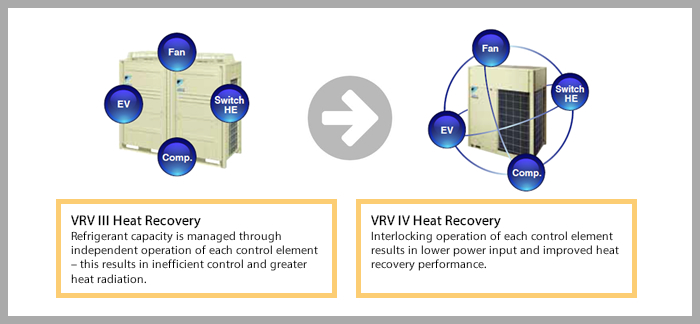

Heat Recovery Link

VRV IV Heat Recovery now features Heat Recovery Link (HRL) to allow for precise and integrated capacity control resulting in better comfort and increased energy savings.

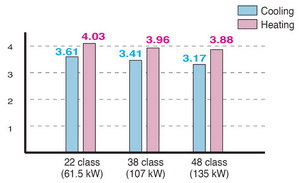

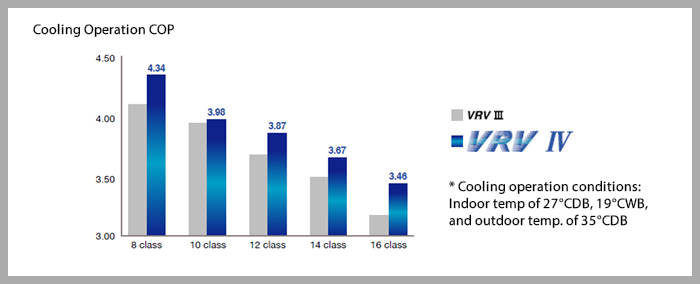

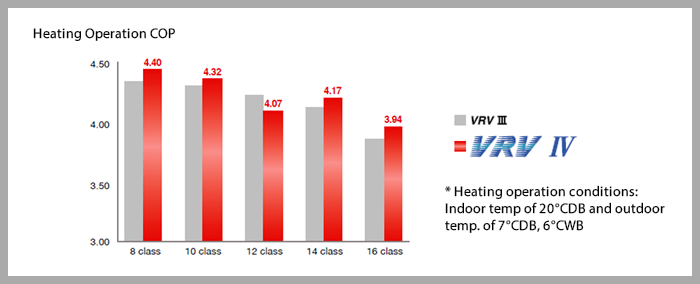

High Energy Efficiencies, EER & COP

It’s essential to take energy efficiency and operating costs into account when specifying an air conditioning system. Daikin’s ongoing commitment to research and development has led to technology advances such as VRT, HRL, streamline airflow and a new advanced J series compact inverter compressor enabling higher efficiencies to minimise your building’s energy consumption while still delivering exceptional cooling and heating performance.

-

Heat Recovery

By incorporating a Branch Selector (BS) unit into your Daikin VRV IV air conditioning system, Daikin VRV IV heat recovery can provide simultaneous heating and cooling across different areas of your building, substantially improving energy efficiency by recovering waste heat from one part of a building and redirecting that heat to another part of the building that requires heating.

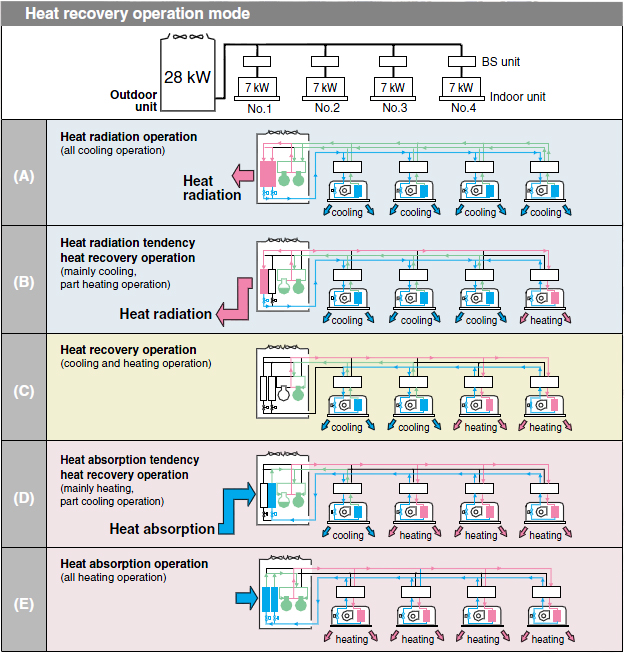

Heat Recovery Operation Mode

Simultaneous Cooling and Heating on the same floor!

Branch Selector (BS) Unit

By adding suction gas piping and a BS unit (sold separately), simultaneous heating and cooling can be provided by a single system, reducing energy consumption and maintaining superior comfort.

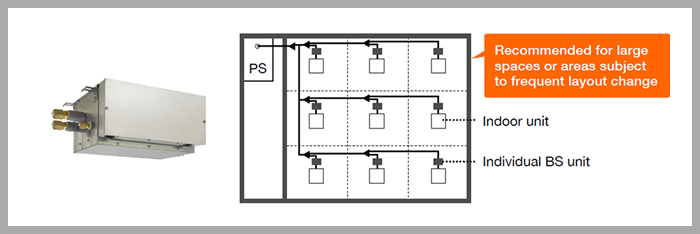

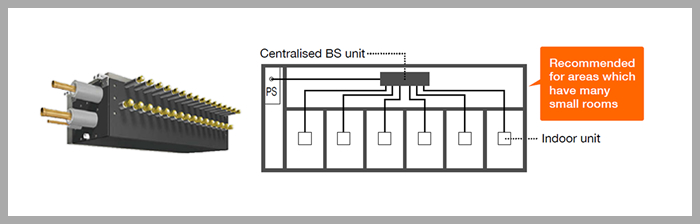

To allow for flexibility in design, two types of BS units are available.

Daikin offers individual BS unit and centralised BS unit types to suit your application needs. Our new range features a more compact, quiet and lightweight design which support indoor units up to 250 Class. Further, our re-engineered centralised BS units are now available in 5 different models ranging from 4, 6, 8, 10, 12 & 16 port options.

The new centralised BS unit is significantly more compact, lightweight and quieter in operations and also enables up to 16kW indoor unit to be connected into a single port or a 28kW indoor unit connected into 2 ports with no loss in capacity.

-

Outdoor Units

The Daikin VRV IV Heat Recovery is now available in two different series, Standard and High-COP type models:

- Standard: Offers high capacity with models ranging from 22.4kW to 168kW, ideal for large commercial applications

- High-COP: Designed with priority in energy efficiency, models range from 44.8kW to 89.4kW to accommodate the most modern energy efficient buildings targeting a high NABERS rating, lower CO2 emissions etc

HIGH-COP TYPE: Double Outdoor Units

16, 18, 20 classTriple Outdoor Units

24, 26, 28, 30, 32 class

STANDARD TYPE: Single Outdoor Units Double Outdoor Units 8, 10, 12 class 14, 16, 18, 20 class 22, 24 class 26, 28, 30 class 32, 34, 36 class

Triple Outdoor Units 38, 40 class 42, 44 class 46, 48, 50, 52, 54, 56, 58, 60 class

-

Technology

In 1982 Daikin launched its first Variable Refrigerant Volume (VRV) air conditioner, since then Daikin has continued to invest heavily in research and development, leading the way in air conditioning technology and innovation with each generation of VRV systems bringing new and improved models and a wider product pool to suit the ever changing market diversity.

The VRV IV is the epitome of Daikin's commitment to continuously innovating and enhancing the range, performance, reliability and flexibility of our VRV air-conditioning systems. The result is a total variable refrigerant volume air conditioning solution with large outdoor capacities, compact design, flexible installation and state of the art energy saving technology (VRT) with greater efficiency than ever before.

- Large capacity inverter scroll compressor made with high strength material and utilizing a thixocasting process housed in a compact casing, 12 class (33.5 kw) compressor utilizing an 8 class (22.4 KW) case.

- Thixocasting allows the adoption of a thin spiral design, the compression volume is increased by 50% enabling greater performance gains.

- Compressor uses compact concentrated motor windings, resulting in smaller coil ends that help reduce winding resistance and improve motor efficiency at Low RPM range. This is a key factor that contributes to VRV IV high COP while being able to maintain low operation noise, optimal comfort and climate conditions.

- Daikin's jump from a 4 pole motor to a 6 pole motor with 50% more neodymium magnets from previous models is able to efficiently deliver more torque and operate at greater efficiency particularly at low loads.

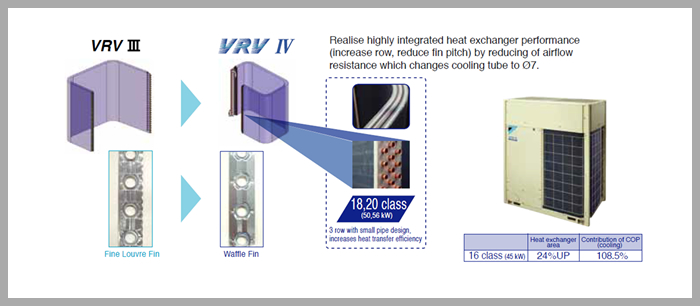

- Low operation noise thanks to an increase in heat exchanger area coupled with a stream line grille design and scroll fan that promotes swirling airflow discharge to reduce vibration and pressure loss.

- Increase heat exchanger surface area of up to 24% over previous models for greater heat transfer efficiency while maintaining a compact installation space.

- VRV IV Inverter Power Module is Refrigerant cooled compared to its air cooled predecessor which results in more reliable operations particularly under high ambient conditions where system integrity may be affected.

- VRV IV Inverter PCB allows stepless frequency control of the compressor from 60 to 408Hz allows precise control to match the required capacity to load and in turn improving energy efficiency.

- Auto-Sequencing Technology: VRV IV unit sequencing operation is automatically enabled on startup and after each 8 hour period of operation to ensure balance operation of each outdoor unit to improve compressor longevity and stability.